sales@cmcarbon.com

sales@cmcarbon.com

The complex structure of graphite determines its special properties. We also require high accuracy for graphite processing. Therefore, during the processing of the graphite, the phenomena such as edge serration, slag falling, and collapse angle can occur in particular.

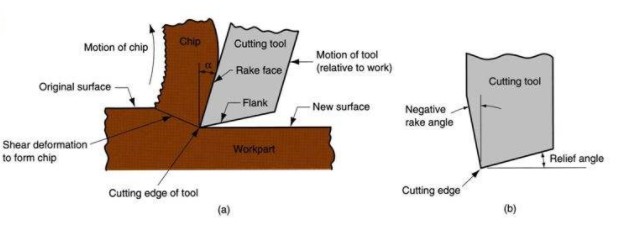

When the graphite is processed with the negative front angle, the cutting edge strength, impact resistance and friction resistance of the cutter are better. With the decrease of the absolute value of the negative rake angle, the wear area of the flank is not changed too much, but it tends to decrease as a whole. When the positive front angle is used, with the increase of the front angle, the cutting-edge strength of the tool is weakened, which leads to the increase of the wear of the flank. When we process with a negative rake angle, the cutting resistance is large and the cutting vibration is increased.

This requires that our processors must have a wealth of experience, then graphite abrasion can be greatly reduced during processing.

CM Carbon Co Ltd is the leading Chinese Graphite Producer, welcome your inquiry of our Graphite Materials, Graphite Machining Parts, Graphite Products, Graphite Felts and CFC

Email sales@cmcarbon.com

Phone/WhatsApp 0086 17200308665